Cold recovery: the energy floating on the high seas [Global Gas Perspectives]

The LNG industry sends more than a million tonnes of cryogenic fuel around the world every day. In addition to the LNG, a cargo of ‘cold’ at about -162°C is delivered. It usually goes to waste.

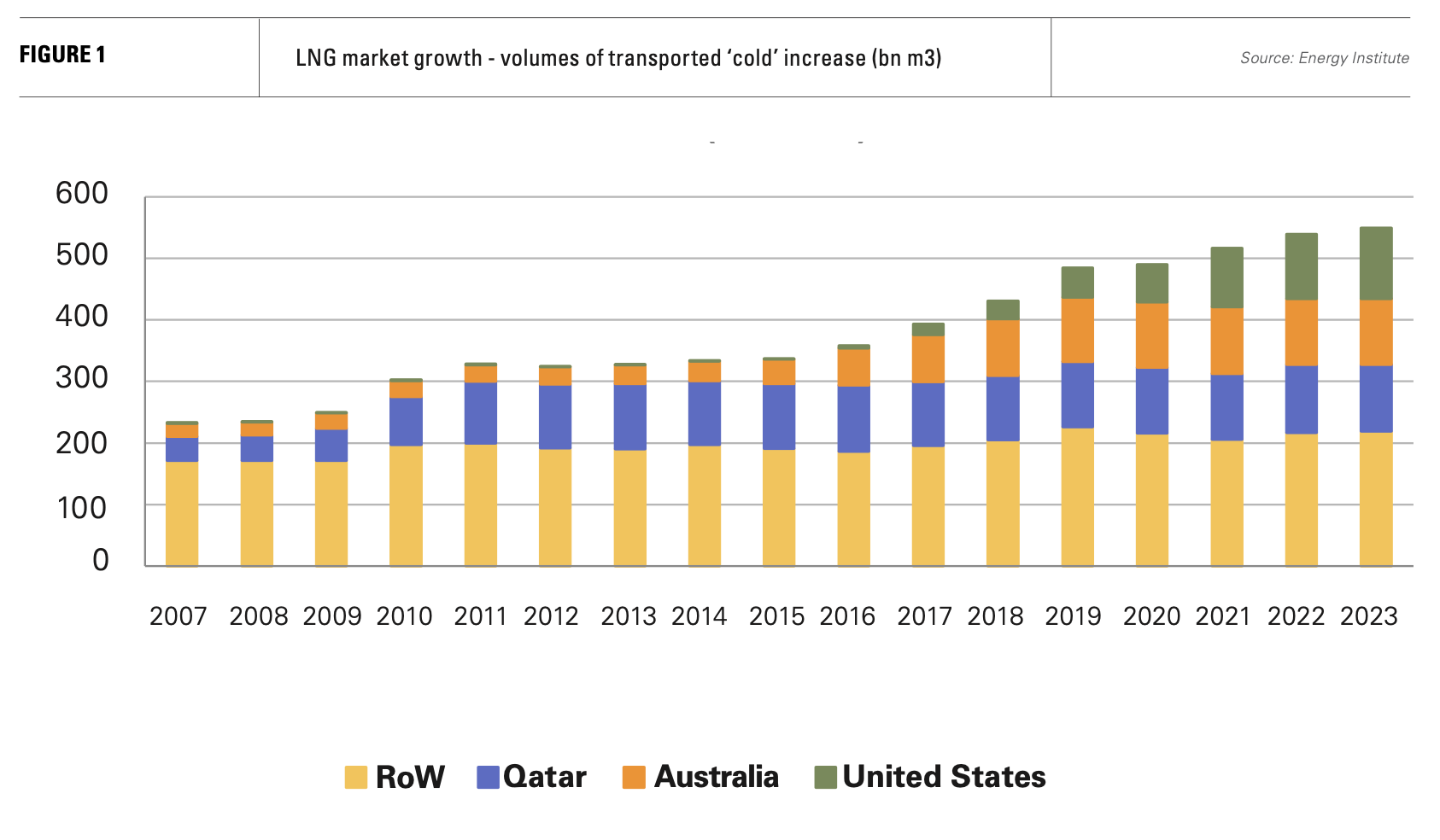

The LNG market has more than doubled in size since 2009 to reach 549bn m3 of gas last year. With the major newbuilding of liquefaction plants under way in the US and Qatar, it is set to grow by another 40% by 2030. The amount of ‘cold’ traversing the world seas and oceans will continue to grow.

Embedded energy

The liquefaction of gas to produce LNG embeds energy in the LNG as a result of its compression and cooling, the recovery of which can be profitable and have a significant impact on the carbon emissions of the entire LNG supply chain. According to engineering company ABB, a 6.25mn tonne/yr LNG facility using gas turbines to run its compressors will consume about 650mn m3 of gas/yr, giving some idea of the energy stored in the LNG.

In its white paper on cold energy recovery, organic rankine cycle (ORC) specialist Exergy estimates that one tonne of LNG requires about 500 kWh of electricity to produce, which accounts for roughly 3.6% of natural gas’ lower heating value.

The company says: “LNG contains immense potential for power generation, known as the ‘cold energy potential’, with available heat of approximately 725 kJth/kgLNG (from -160°C to 15°C at 80 bar), and mechanical exergy from the gasification process alone amounting to about 348 kJex/kg.”

ABB estimates that an electrically-driven compression system for the same size of LNG facility uses 30% less gas, generating savings of $45mn/yr at $200/t. This lower carbon LNG cargo would still have the same cold energy storage as a higher carbon cargo; in effect it would be transporting a portion of clean energy from, for example, Australia to Japan embedded in a fossil fuel.

Moreover, liquefaction processes have steadily become more efficient, using less energy to achieve the same result. A side effect of this is the more efficient creation of cold energy potential.

Liquid expansion

Exploiting the potential of a cryogenic fuel takes different forms. Back in the early 2010s, liquid air as an energy carrier gained attention. Although posited originally as a means of decarbonising road transport via the use of liquid air engines for vehicles, its first commercial-scale application has been as energy storage, pioneered by UK company Highview Power.

Liquid air releases its energy through expansion when exposed to ambient temperatures, creating a usable force to drive an electric generator. Energy is stored in the liquid air by means of compression, cooling the gas down to -196°C. It is a process designed specifically around the mechanical energy contained within a cryogenic fuel.

A liquid air style engine may or may not be a suitable means of energy recovery for LNG because, unlike liquid air, LNG is flammable. However, if that problem is solvable, a significant proportion of the energy used to compress the natural gas could be recovered emissions free, increasing the value of the LNG cargo to the buyer and reducing the overall carbon footprint of the LNG supply chain.

A liquid air engine approach might seem somewhat esoteric, but other methods – ORC and direct air cooling systems – are already being deployed.

Regasification: a wasted opportunity

LNG is regasified by being passed through a vaporiser. The temperature of the LNG is increased by running it through a heat exchanger, in which sea water, air or secondary fluid is used to heat the LNG. Pressure is reduced through the expansion of the gas in special tanks.

Exergy says common vaporisation methods consume energy. Submerged Combustion Vaporisation (SCV) involves heating water with gas burners and then running the LNG in pipes through the resultant hot water bath. Open rack vaporisation (ORV) uses sea or freshwater as the heat source, and is more energy efficient as a result. Intermediate-fluid vaporisation (IFV) uses a secondary fluid which is vaporised and then circulated through a heat exchanger where it condenses, transferring its heat to the LNG, which is reconverted to natural gas as it warms up and expands.

These processes require electrical energy for pumps and about 28% of the energy used during liquefaction is lost to the environment, according to Exergy.

Spanish regasification terminals lead cold energy recovery

Cold energy recovery has certainly gained attention in Spain. Finnish heat exchanger provider Vahterus and Spain’s Enagas have developed a cold box system. High pressure LNG is passed through two heat exchangers, one using an intermediate fluid and the second using a refrigerant. There is no need for pumping, increasing the energy efficiency of the process.

The cold energy of the LNG is recovered by the refrigerant and can be delivered to customers. As regasification terminals are sited in ports, there is often a local need for cold in refrigerated warehouses, but data centres, ice factories and other industrial applications are also possible. Enagas hopes that the availability of urban grid cooling systems will attract industries in need of cooling, such as data centres, to ports with regasification terminals.

The cold box system was tested in a 35-kW prototype from 2018 to 2020 and a 370-kW system has been built at the Huelva regasification facility in Spain.

Enagas also has a new residual cold recovery system at its Barcelona regasification terminal developed in cooperation with France’s Veolia. The system is expected to provide 131 GWh of energy, avoiding 42,000 y/yr of CO2 emissions.

Barcelona LNG uses a seawater loop to heat LNG and convert it back into natural gas. The cold is lost to the sea. The cold recovery system allows the cold to be recycled and reinjected into the urban grid for cooling, avoiding the use of electricity. The Palacio de Congresos and the Mercabarna, a major food market, are customers.

ORC systems recover cold and generate power

ORC systems do even better.

In an ORC system, seawater passes through a series of heat exchangers where it vaporises a low boiling point fluid. The high-pressure vapour expands in a turbine to generate electricity before being discharged into condensers where it releases its heat to the LNG, causing it to vaporise. Unlike the conventional IFV approach, the ORC system converts the cold energy to electrical power using a turbo expander.

Exergy has improved a single condensation level ORC system to create a multi-level system which enhances system efficiency and maximises power generation at the required regasification rate with a single feed pump. Although the patented system can use four levels of condensation, Exergy says two pressure levels often prove the optimal compromise between efficiency, plant complexity and overall capex.

Based on a 1mn-t/yr regasification terminal with an LNG flow to the ORC of 180 t/hr, Exergy’s two-pressure level ORC system generates 18% more power than a conventional ORC, equivalent to 4.3 MWe or 37 GWh/yr. It would increase avoided CO2 emissions from 8,300 t/yr to 9,600 t/yr based on an emissions factor of 260 gCO2/kWh.

The potential of ORC systems certainly looks good. In a 2023 research paper, Cold Energy recovery from the LNG regasification process for data centre cooling and power generation, researchers Sandeep Yadav and S. Srinivas simulated the use of recovered cold from a 5mn t/yr LNG regasification terminal in India, using a cogeneration system based on an ORC to power a data centre with 5,000 racks. The two-stage system would use ethane and propane as the working fluids. The results were impressive.

The simulation showed that a double-stage ORC system could completely meet the data centre's cooling requirement of 34.6 MW. In addition, it would generate 15.8 MW of power, providing 46% of the data centre's electrical demand. The economic analysis suggested a Levelized Cost of Electricity of just $0.04/kWh and an internal rate of return of 29%. The system would result in an annual reduction of 210,000 t of CO2 emissions. The paper was published in Volume 238 of the journal Energy.

ORC systems, also known as binary power plants, have become the preferred option for geothermal power plants, replacing flash steam solutions. The technology has been in use since the 1980s with typical applications in biomass and solar thermal power plants, wastewater and effluent heat recovery systems as well as geothermal power.

Liquefaction plant developers are trying to reduce their carbon footprint. At the other end of the transport chain, regasification terminals now have the chance to do the same and increase their profits simultaneously.